What is Root Cause Analysis. Root cause analysis RCA for software defects is an approach developers use to better understand why a fault occurred and to take steps to drive improvements.

Http Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 81 4664 Rep Rep1 Type Pdf

Usually we use RCA as a way to diagnose problems.

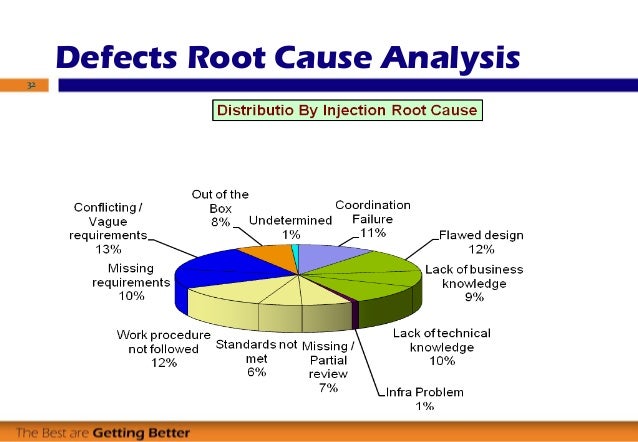

Defect root cause analysis. Root Cause Analysis template Excel. When applied to process analysis this method is called process failure mode and effects analysis PFMEA. At the most basic level root cause analysis is a process used to identify the underlying cause of a defect or failure.

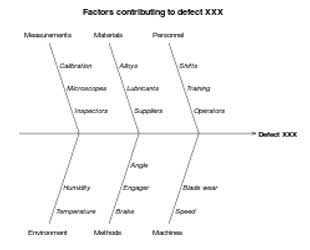

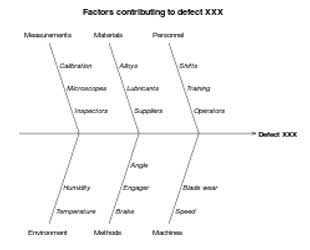

To reduce the frequency of such defect generation you can do the root cause analysis. While a Root Cause Analysis excel document may take the following format. Diagram for root cause analysis for defect.

Use of Root Cause Analysis. Root cause analysis RCA is a specific technique you can use to troubleshoot problems. A Root Cause Analysis process applies a problem-solving methodology to identify and control the root causes of these defects.

We brainstorm read and dig the defect to identify whether the defect was due to testing miss development miss or was a requirement or designs miss. A Root Cause Analysis process applies a problem-solving methodology to identify and control the root causes of these defects. It is widely used in IT operations telecommunications industrial process control accident analysis eg in aviation 2 rail transport or nuclear plants medicine for medical diagnosis healthcare industry eg for epidemiology etc.

No matter which tool you use root cause analysis is just the beginning of the problem-solving process. Root cause analysis is used in software testing to identify defects. It is resulting in the loss of money time and reputation.

Defects can affect a software product or its functionality such as the failure of a featurefunctionality or the complete system failure. With this technique you analyze the issue at hand using a particular set of steps to identify the primary cause of the problem. So Root Cause Analysis discovers what went wrong.

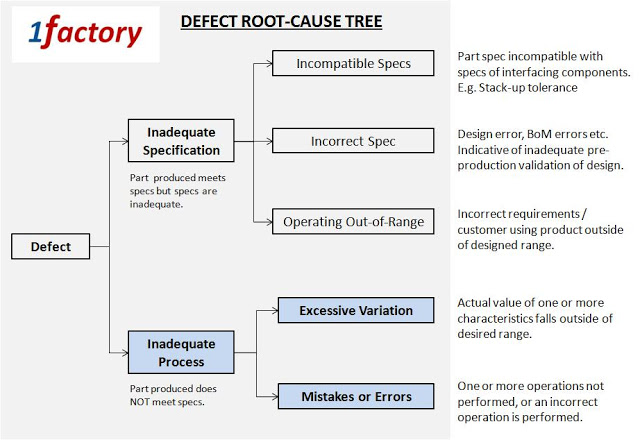

This classification works whether a defect is found in manufacturing or in the field and will help you initiate root-cause analysis in a more collaborative manner. How to Use Root Cause Analysis for Software Defects. Here are a few more quick and easy to replicate examples of simple Root Cause Analysis templates.

Defects Root Causes and Effects. The term root cause refers to the most primary reason for a production lines drop in quality or a decrease in the overall equipment effectiveness OEE of an asset. Its typically used to identify the cause of problems and address that instead of just treating the symptoms.

The process is akin to how a medical team wants to diagnose and cure a patients illness rather than simply treat the symptoms. Working with agile methodology we were implementing new features as fast as the speed of light. The defect root-cause tree below provides some examples about what types of defects are classified into each category.

A company may choose to have a single methodology or to have a choice from a number of different methodologies to accommodate the various complexities significance and nature of problems. Oil stains dirt spot a rust spot 4. Defect Root Cause Analysis.

A company may choose to have a single methodology or to have a choice from a number of different methodologies to accommodate the various complexities significance and nature of problems. As it relates to product development RCA is a systematic process for categorizing and analyzing defects that have occurred pre-release post-release or both. Many manufacturers use PFMEA findings to inform questions for process audits using this problem-solving tool to reduce risk at the source.

Treat every defect seriously. The root cause analysis of defects can be done using various techniques but we will focus on the 5W1H method here. RCA Root Cause Analysis is a mechanism of analyzing the Defects to identify its cause.

Root Cause Analysis is the technique of uncovering the primary cause of a problem. Root cause analysis is the method in which the reason for the cause of the defect is evaluated and identified so as to identify the containment corrective and preventive action which will contribute to the prevention of the defects recurrence. Defects in this process are typically identified as having several root causes hence the term.

That means you can find the cause of software defects before your customers find bugs. Root Cause Analysis This is the method of finding the reason that contributes to the defect. RCA is based on the principle that its not useful to cater to the symptoms of a problem while ignoring its roots.

On the production floor Root Cause Analysis RCA is the process of identifying factors that cause defects or quality deviations in the manufactured product. They can be made into neat lists or more structured diagrams to suit your own management style. There are many circumstances which cause an item to have an incorrect dollar amount assigned to the final balanced amount updated for posting.

You know any broken stitch in a garment is a critical defect. It is an essential part in the elimination of causes that leads to the defects. Finding the root cause for broken stitch Broken stitches are commonly found in a garment seam.

The key points that underlies the root cause analysis of a defect are-. In science and engineering root cause analysis RCA is a method of problem solving used for identifying the root causes of faults or problems. Discover how Root Cause Analysis RCAhelped us to learn from our mistakes and reduce our bugs by 37.

Guide To Root Cause Analysis Steps Techniques Examples

Guide To Root Cause Analysis Steps Techniques Examples

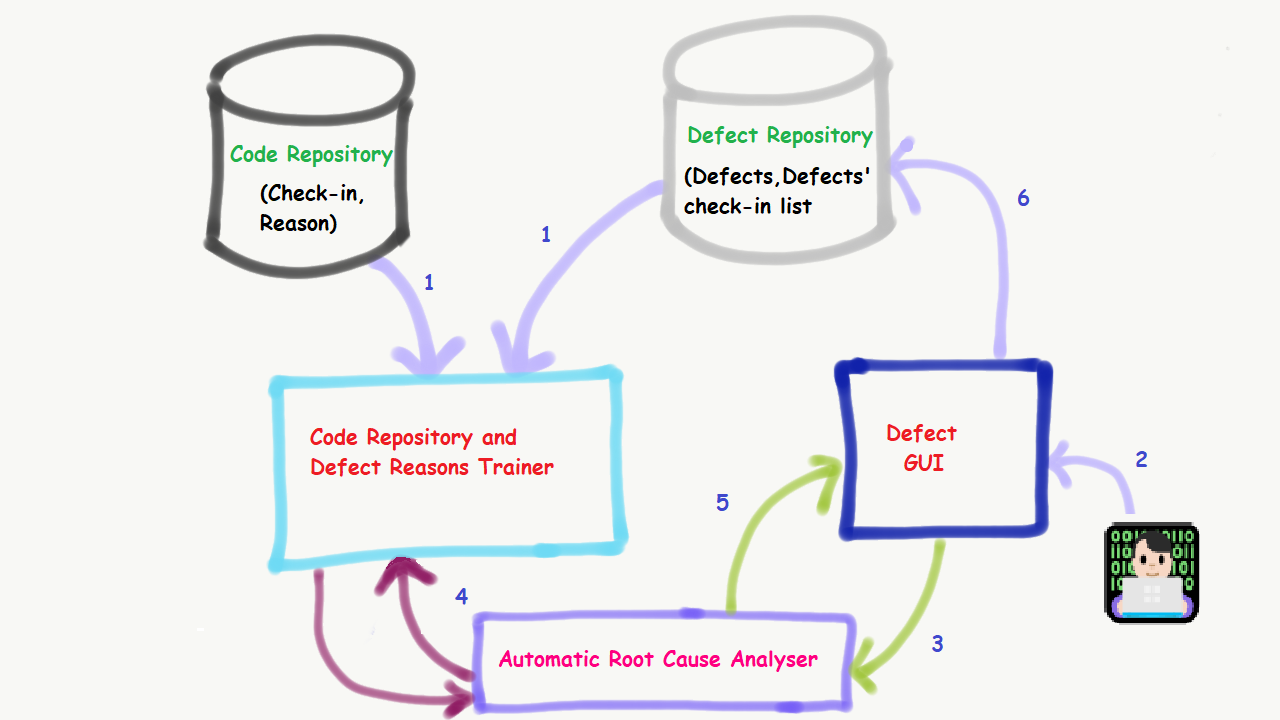

Automated Root Cause Analysis Dzone Security

Automated Root Cause Analysis Dzone Security

Applying Root Cause Analysis To Software Defects

Applying Root Cause Analysis To Software Defects

Rca Root Cause Analysis Quality One

Rca Root Cause Analysis Quality One

What Is Root Cause Analysis In Testing Quora

What Is Root Cause Analysis In Testing Quora

Software Defect Root Cause Analysis

What Is Defect Root Cause Analysis And Effects In Software Testing

What Is Defect Root Cause Analysis And Effects In Software Testing

Guide To Root Cause Analysis Steps Techniques Examples

Guide To Root Cause Analysis Steps Techniques Examples

Using Root Cause Analysis For Powerful Defect Prevention Medtech Intelligence

Using Root Cause Analysis For Powerful Defect Prevention Medtech Intelligence

Root Cause Analysis For Software Testers

Root Cause Analysis For Software Testers

Root Cause Analysis For Software Testers

Root Cause Analysis For Software Testers

Software Defect Root Cause Analysis

Defect Root Cause Analysis Where Do You Start 1factory

Defect Root Cause Analysis Where Do You Start 1factory

Root Cause Analysis Of Pin Hole Defects See Online Version For Colours Download Scientific Diagram

Root Cause Analysis Of Pin Hole Defects See Online Version For Colours Download Scientific Diagram