The Quenching and Aging Heat Treatment Process. That said the basic process is generally the same.

Heat it up to a certain temperature hold it at that temperature then cool it down.

How to heat treat aluminum. When the term is applied to aluminum alloys howev-. This alloy can also withstand environmental conditions including sea water. Extrusion temperature is the most basic and critical process factor for extrusion production.

Subsequent heat treatment at tower temperatures ie. If this temperature is not achieved the solution heat treatment will not be successful. Preheating or homogenizing to reduce chemical segregation of cast structures and to improve their workability.

Below is a list of the heat treatments commonly used for aluminum and their designations. Heat Treatment of Aluminum Castings. After youre done working on it its pretty easy to restore the temper of the aluminum with a little bit more heat treating.

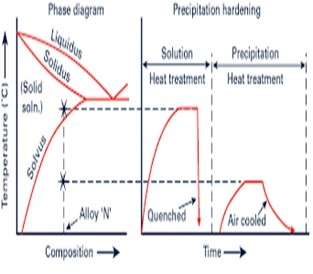

In heat treatable alloy systems like 7XXX 6XXX and 2XXX the al-loying elements show greater solu-bility at elevated temperatures than. Most aluminums require aging to maximize and stabilize their properties. It is different in so much as the solution as treatment which involves heating the aluminium alloy up to its appropriate solution temperature followed by quenching rapidly this makes the alloy extremely soft.

Heat treating 6061 aluminum makes the part physically stronger and helps keep its shape after forming. At that point the basket containing the parts is dropped into a quench tank. In the heat treatable alloy systems like 7XXX 6XXX and 2XXX the alloying elements show greater solubility at elevated temperatures than at room temperature.

Precipitation hardening process can be performed at 160C 320F for 18 h followed by air cooling. Aluminum alloys are classified as either heat treatable or not heat treatable depending on whether the alloy responds to precipitation hardening. We pour some molten aluminium to make bean-can round stock and run.

Aluminium Aluminum 6061 alloy is heat treated at 533C 990F for a sufficient period of time followed by quenching in water. 240 wheels per hour solution heat treat line for forged aluminum wheels. Obviously this is going to really be dependent on the grade of aluminum.

Aluminum Solution Heat Treating. Aluminum Heat Treating Aluminum Solution Heat Treat-ing Aluminum alloys are classified as either heat treatable or not heat treatable depending on whether the alloy responds to precipitation hard-ening. If you would like to submit an enquiry please get in touch.

Time at temperature for solution treatment depends on the type of alloy and the furnace load. Pure aluminum and aluminum alloyed primarily with manganese or magnesium does not respond to heat treatment so this article will focus on the aluminum alloys that contain copper zinc or a blend of magnesium and silicon as these respond to heat treatment favorably. Ageing or natural ageing at room temperature allows for a controlled precipitation of the constituents thereby achieving increased hardness and strength.

Aluminum extrusion and heat treatment processes optimizing. Annealing to soften strain-hardened work-hardened and heat treated alloy structures to relieve stresses and to stabilize properties and dimensions. The alternate for T6 is 6 Hrs at 360F.

Many age at room temperature over a period of time. Extrusion temperature has a great impact on product quality. 95 wheels per hour solution heat treat line for cast aluminum wheels.

The general types of heat treatments applied to aluminum and its alloys are. Some do require heat treatment. Together these properties make this alloy a great option for pipes machine parts and as a construction material in everything from roofs to bridges to aircraft structures.

The precipitation treatment for tempers T5 and T52 are 400F and 450F for 1 Hr while the T6 treatment is 8 Hrs at 350F. Testing out an easy DIY heat treatment process anyone can do in a standard kitchen oven. The process of aluminium solutionizing treatment is slightly different to that of steel heat treatment.

This process is again repeated at 177C 350F for 8 h followed by cooling in air. Not all require heat treatment to promote aging. The solution treatment can be done by controlling the extrusion temper and quenching from that temperature.

Heat Treating of Aluminum Alloys HEAT TREATING in its broadest sense refers to any of the heating and cooling operations that are performed for the pur- pose of changing the mechanical properties the metallurgical structure or the residual stress state of a metal product. The process of taking a 6061 aluminum part in O condition to a stronger more durable condition begins by heat treating the parts at 985 degrees Fahrenheit for an hour in a drop bottom furnace. 1Billet heating and extrusion temperature.

Jones Metal is Nadcap certified in Aluminum Heat Treating Services and is proud of 99 on-time delivery. The exact temperature for solution heat treatment depends on the alloy composition of the aluminum but it typically occurs somewhere in the range of 825F to 980F but the temperature used must be within 10F of the target temperature.

How It Works Heat Treating Aluminium Youtube

How It Works Heat Treating Aluminium Youtube

Heat Treating Aluminium Easy Diy Method Youtube

Heat Treating Aluminium Easy Diy Method Youtube

Industrial Aluminum Solution Heat Treat Furnaces Heattek

Industrial Aluminum Solution Heat Treat Furnaces Heattek

To The Point Heat Treating Aluminum Frames Pinkbike

To The Point Heat Treating Aluminum Frames Pinkbike

Heat Treating Of Aluminum Alloys Engineers Edge Www Engineersedge Com

Heat Treating Of Aluminum Alloys Engineers Edge Www Engineersedge Com

Heat Treatment Process Overview For Fasteners Part 2 2016 06 22 Industrial Heating

Heat Treatment Process Overview For Fasteners Part 2 2016 06 22 Industrial Heating

Solution Heat Treat Furnace Drop Bottom Furnace International Thermal Systems

Solution Heat Treat Furnace Drop Bottom Furnace International Thermal Systems

Aluminum Heat Treating How It Works Youtube

Aluminum Heat Treating How It Works Youtube

3 17 Heat Treatment Of Aluminum Alloys

How It Works Heat Treating Aluminium Youtube

How It Works Heat Treating Aluminium Youtube

The Heat Treatment Of Aluminum Alloys The Monty

The Heat Treatment Of Aluminum Alloys The Monty

T6 Heat Treatment For Aluminum Forgings

Heat Treatment Of Aluminum Part Ii Thermal Processing Magazine

Heat Treatment Of Aluminum Part Ii Thermal Processing Magazine

.jpg)

.jpg)